Smart Factory

Smart Factory

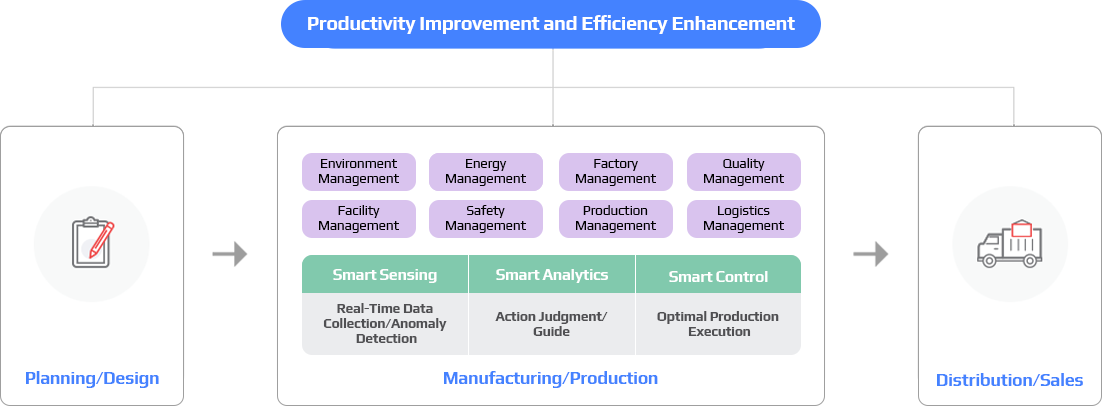

WeZON's Smart Factory is a factory that can self-monitor and -control based on real-time data collected and analyzed through

sensors installed on equipment and machines(IoT) with clear visibility of the factory’s operation.

In response to the ‘Smart Factory Support Project’, the government supported the completion of 30,144 Smart Factories until 2022 and

the companies that adopted smart factories have achieved increased employment and improved productivity.

WeZON is a company that has already been registered in the pool of suppliers in the Smart Factory promotion group and our goal is to grow

together with companies in demand by providing stable services ranging from consulting and system establishment to post-management

based on our experience of over 20 years in supplying industrial IT solutions.

Please contact us if you are a company with plans to ‘build and upgrade new smart factory-related systems.

Introduction of

Smart Factory

An intelligent factory in the 4th Industrial Revolution era that enables data accumulation and utilization in manufacturing process,

production, and delivery management

Performance of

companies that

adopted

Smart Factory

Smart Factory

supply and

distribution

status

Smart Factory

adoption inquiry

process & method

Smart Factory

adoption inquiry

Counseling and

on-site inspection

by WeZON consultant :

Establish construction plan /

Total project cost estimate

Decide optimal support business type

(New/Advancement)

Prepare business

plan (WeZON)

and project support

Install Smart Factory

after the selection

Stabilization and

post-management

Smart Factory

project vision

Our goal is to grow together with our customers “as the world’s top-class

software solution company in the plant & production field within 10 years.”

We will focus on providing integrated systems in the manufacturing and environmental fields and on improving the ease of use.

By gradually ‘adding and expanding’ various solutions or functions, the data will be easily linked(API provided)

and conveniently used as a single system in the future.

Introduction to

supportable solutions

Factory

Management Suite

We provide “Factory Management Suite” based on equipment production management and quality process monitoring.

Product inquiry

02-555-7401

smart@wezon.com

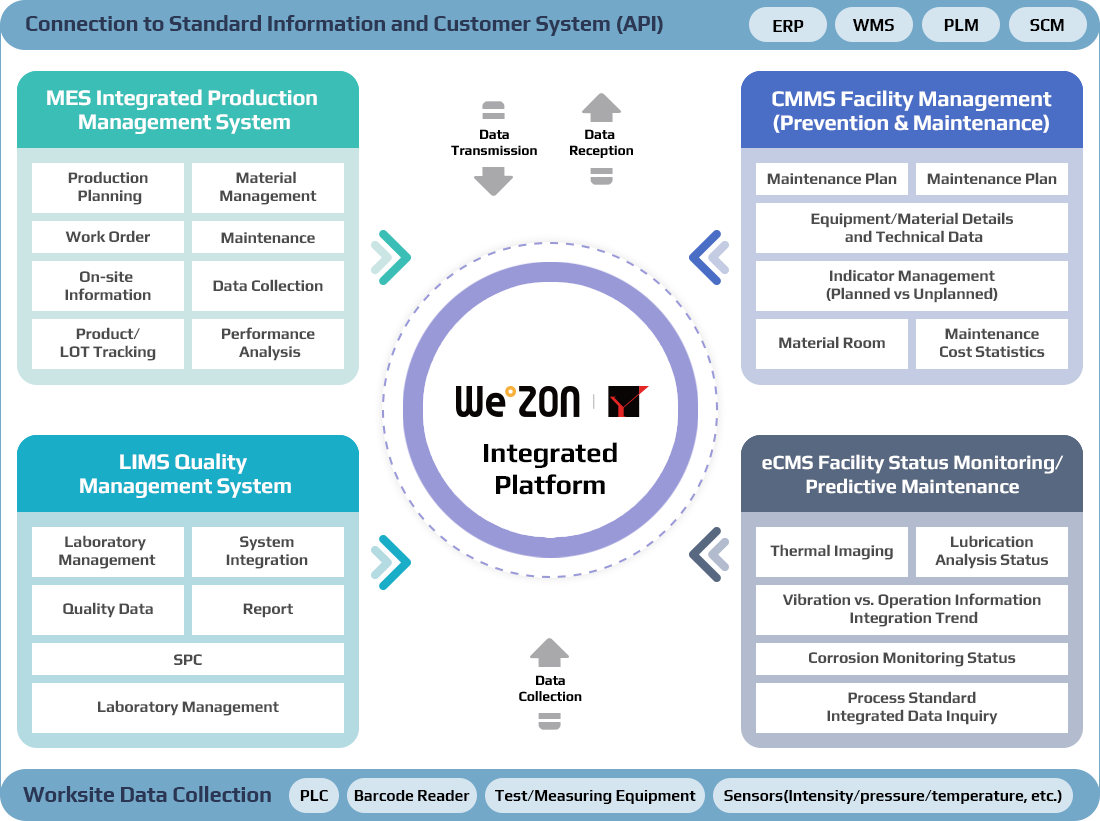

Manufacturing Execution System

WeZON MES: Production management system

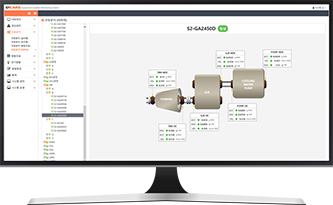

WeZon's integrated production management system(Manufacturing Execution System, MES) aims to optimize operations by recording

and integrating data created during material purchasing, production planning, and process work at the factory site.

It is not just a tool for planning, but an execution system for controlling and managing the actual manufacturing process and work progress.

WeZON MES

On-Premise

based production

management solution

MES is not just a simple field information collection software, but an integrated production management system that accompanies

companies on their journey to build a successful Smart Factory.

WeZon MES obtained GS certification level 1 in June 2022, and it is supplied to small and medium-sized manufacturing companies.

Key functions include production planning, material management, real-time process monitoring, quality operations,

and resource allocation and control.

Importance

-

01

Supports connection and integration

Supports connection with legacy systems and integration of various communication protocols

-

02

Provides industry-specific solutions

Provides industry-specific MES solutions applying SW development know-how of over 20 years of business experience

-

03

One-stop service throughout the entire process

Provides one-stop service throughout the entire process from field analysis – consulting – design – construction that reflects

the characteristics of each industry -

04

Project implementation and Korean Standards Association partner

Implements multiple projects to spread Smart Factory supply and is a partner of the Korean Standards Association

Key functions

Expectations

-

Systematic work plan(Weekly/Monthly)

Secures flexibility in production plans according to customer orders and ordering plans

Check equipment/manpower/material availability

-

Check real-time manufacturing site production information

Improves production information accuracy/speed

Real-time check of production progress compared to branch

Improved quality through quick identification of defects/abnormalities

-

Quick work order confirmation

Quick response to emergency production, changes in work details, etc.

Supports quick sharing

-

Reduces paperwork

Reduces computer input time through real-time data collection and automatic analysis

Automatic generation of statistics reports on comprehensive equipment efficiency

Increased work efficiency by automating performance input

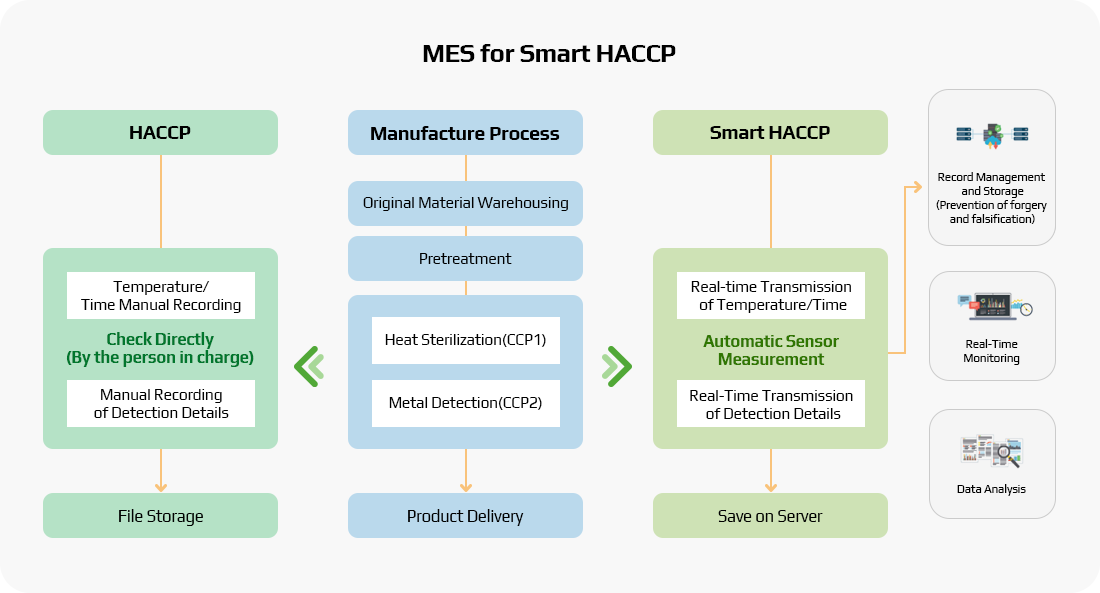

MES for Smart

HACCP

Smart HACCP

solution for food

safety management

Integrated with ICT technology, Smart HACCP management system achieves quality assurances with collection/management/analysis of data,

which include digitizing all the data produced during the manufacturing process and automating the monitoring of important control points

and key processes.

Process

Key functions

Product inquiry

02-555-7401

smart@wezon.com

Computerized maintenance management system

SWING CMMS : Equipment management system

WeZon SWING CMMS is equipment asset management software for equipment maintenance personnel and equipment management departments.

SWING CMMS is a system developed to suit realistic situation by incorporating the advantages of advanced maintenance work processes(Best Practice)

Even users who are not familiar with the system can easily begin systematic equipment management tasks

Importance

-

01

Convenience of use

Work can be processed with multiple work screens displayed at once

Additional advanced search can be used in addition to basic search conditions

Additional advanced search can be used in addition to basic search conditions

Search function for help on key information, and hash tags

-

02

Supported services

Provides templates for preparing standard information and preventive maintenance schedules

Provides templates and guides for organizing past maintenance history

Supports optimized scheduling of establishment procedures to minimize on-boarding time

* Migration of preventive maintenance master and maintenance history data other than standard information is optional

-

03

Connection and expansion of related systems

Connected with existing legacy systems(HR, SSO, etc.)

Expansion of equipment status monitoring and predictive maintenance solutions

Data collection on the status(temperature, pressure, vibration) of key equipment

It supports the establishment of an instability prevention maintenance process through Planned vs. Unplanned Task management,

and provides basic support for uploading and verifying standard information and user training to minimize system on-boarding time

In addition, it provides a solution for real-time collection of on-site equipment status data, supports on-site installation(construction)(optional)

manages equipment status alarms, and can be used as data for predictive maintenance based on accumulated data.

Process

Key functions

| Work request, order and history management |

|---|

| When equipment abnormalities are discovered, quickly normalizes equipment through work requests, work orders, and history management |

| Confirmation and management of equipment & maintenance material information |

|---|

| Easy checking of basic information such as basic specifications, location and quantity, and price of equipment and maintenance materials |

| Report and statistics |

|---|

| Generate various reports and is easy to check statistics such as maintenance costs by equipment, work compliance rate by department, preventive maintenance rate, preventive inspection performance rate, etc. |

| Preventive maintenance & inspection plan |

|---|

| Establishment of preventive maintenance and inspection plans for each facility using a calendar, and efficient maintenance activities through a work list |

| Status view(Dashboard) |

|---|

| Check the status of facilities and work status at a glance, and manage related data |

Expectations

Enhanced equipment

management

-

Enhanced equipment operation rate

Prevents unexpected failures by analyzing maintenance data such as equipment down time,

number of failures, and working hoursReduce accident rate through preventive inspection for repetitive defects

-

Reduction in maintenance costs

Reduced logistics and inventory costs for repair materials

Reduced emergency purchase of repair materials Reduced purchase costs

Reduced excessive overtime Reduced overtime pay

Excludes inappropriate input from external service providers

-

Improved maintenance management structure

Strengthened collaboration within the factory through mobile apps

Real-time information sharing between multiple working level personnel

and approval authorities Quick/accurate decision-makingClear responsibilities and authority

Systematic accumulation and sharing of know-how through standardization of work procedures and methods

-

Facility asset management

Integrated management of facility asset information(Connected facility structure of location

and type supports efficient maintenance activities)Extended lifespan of facilities and parts through optimal management

Continuous improvement of the facility management process

Product inquiry

02-555-7401

smart@wezon.com

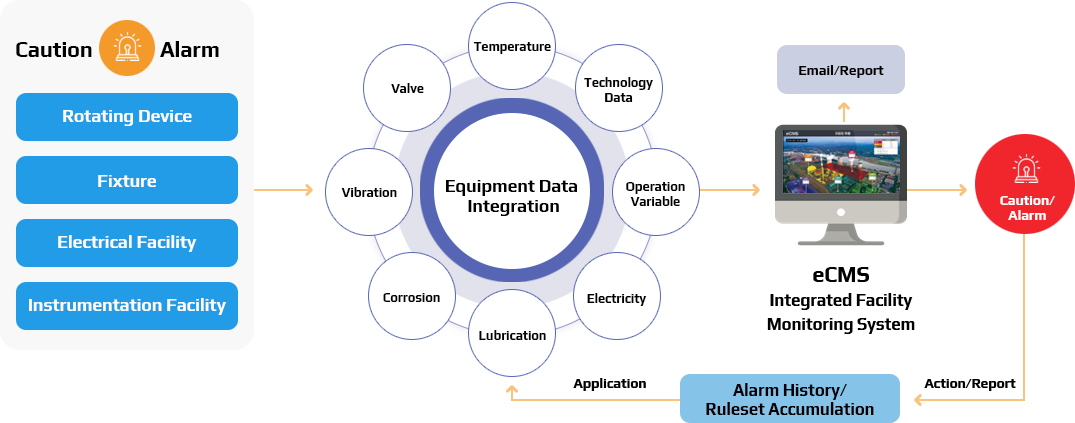

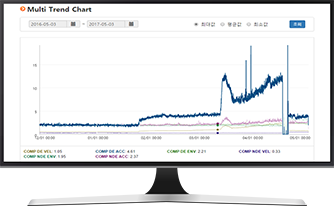

Equipment Condition Monitoring System

Equipment Condition Monitoring System(eCMS)

Integrated facility status monitoring system aims to improve work efficiency and to continuously improve facility availability by performing facility monitoring/alarm confirmation/reporting/knowledge sharing through integrated management of predictive maintenance data

Key products

Imaging measurement data

Vibration-Multiple trend

Importance

Data generated from various systems across the company exist in separate local systems in the process network,

making it difficult to utilize and share inspection results or past data.

WeZon's Equipment Condition Monitoring System(eCMS) is an ‘integrated system’ that integrates and links individual status monitoring

and periodic system data dispersed across the factory to efficiently process alarm confirmation, reporting, and knowledge sharing.

System

configuration

diagram

Key functions

| Dashboard |

|---|

Factory status |

Status by factory |

Alarm List(Facility) |

Alarm List(Location) |

Alarm List(Lubrication) |

Alarm List(Corrosion) |

Temperature status by channel |

Alarm List(Temperature)) |

Temperature status of entire factory |

Alarm List(PD) |

PD status of entire factory |

| Alarm management |

|---|

Vibration Alarm(By factory) |

Vibration Alarm(By equipment) |

Vibration Alarm(By system) |

Vibration Alarm history |

Lubrication Alarm history |

| Daily inspection |

Daily report |

Weekly report |

Send report |

PM performance management(Weekly) |

PM performance management(Monthly) |

| Vibration analysis |

|---|

Vibration analysis(By equipment) |

Vibration analysis(By location) |

Vibration analysis(Integrated search) |

Vibration analysis(Image) |

| Statistics |

Alarm occurrence status |

Alarm action status |

Equipment code matching status |

Vibration On/Off line status |

| Status search |

|---|

Lubrication analysis result |

MOMOS result |

Process load |

Corrosion monitoring status |

| Electricity status |

Temperature monitor(By channel) |

Temperature monitor(By location) |

PD monitor status |

Expectations

-

Enhance work efficiency

Intuitive status identification through information integration and visualization

Share situations and reduce response time

Supports quick decision-making by reducing alarm/failure analysis time

Increased work efficiency and reduced human error through off-line system integration

Simplified work and reduced time through report systemization

nhanced members satisfaction level with workload reduction

Monitoring of actions managed through irrationality list and F/U list

Enhanced work satisfaction level and focus on improving safety/environment/health/process

-

Strengthened safety and protection posture

Accumulation of equipment fail history/diagnosis history and improved accessibility

Accumulation and sharing of equipment diagnosis knowledge

Company-wide synergy effect through knowledge sharing

Utilize internal training - Foster experts

Obtain the foundation for smart diagnosis laid through accumulation of diagnosis history

Sustainable knowledge growth

Product inquiry

02-555-7401

smart@wezon.com

Mobile Field Logging System

Mobile Monitoring System MOMOS

MOMOS connects mobile devices with vibration and temperature measuring instruments, automatically inputs the measured values from the measuring

instruments into the mobile device in real time, and performs inspection tasks to enable real-time sharing of equipment information and prevention of equipment accidents.

Importance

-

01

Mobile utilization

Various data measured in the field can be utilized online immediately.

-

02

Increased convenience of patrol work

During patrol work, information can be entered directly via mobile without having to write it manually on paper.

-

03

Reduce personal work load

Work overload is reduced through automation/computerization of inspection tasks, and field employees can utilize multiple data simultaneously.

-

04

Standardization of measurement results

Setting of legal inspection, equipment inspection, and operation inspection is feasible, as well as adjusting the inspection cycle.

-

05

Diagnosis of abnormal equipment becomes feasible

Setting legal, equipment, and operational inspection and adjusting the inspection cycle become feasible.

-

06

Utilization of data with other systems

By connecting with Yullin Technology's eCMS and SHE system, data such as equipment monitoring and statutory inspection targets can be shared.

-

07

Monitoring of the manager’s work status(KPI)

The implementation rate and non-inspection rate by task and inspection, as well as the inspection plan rate and inspection results by team and task can be identified.

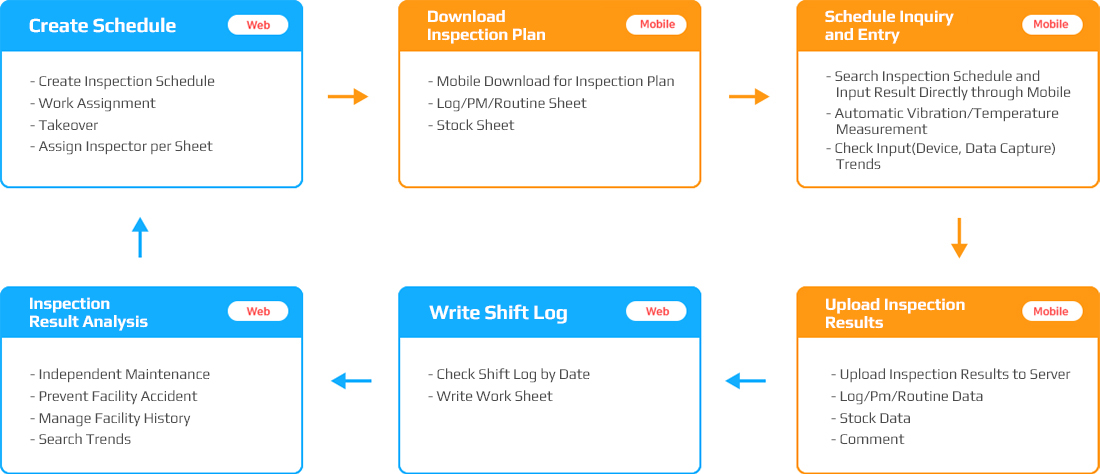

Process

Key functions

| Web Part | ||

|---|---|---|

| Dashboard | Inspection work | Equipment management |

Approval work |

Inspection history and plan |

Equipment abnormality management |

Basic work |

Inspection status |

Equipment/inspection, |

Shift journal |

Search inspection sheet |

|

Work assignment |

Bulletin board | My Page |

| Status management | Bulletin board |

My approval |

Performance statistics |

Reference room |

Favorites |

Report |

||

| Mobile Part | |

|---|---|

| Inspection mode | Other functions |

Sheet inspection mode |

Log-in/out |

Inventory inspection mode |

Attach photo |

Download inspection plan |

QR/RFID |

Upload inspection plan |

|

| Shift journal | |

Search shift journal |

|

Expectations

-

Enhanced work efficiency

Increased work convenience through automatic task assignment and mobile inspection according to the inspection cycle

Minimize work errors and reduce work load by computerizing inspection work

Objective equipment/operation inspection : Prevent human errors

Paperless work environment

Improved satisfaction level among field workers and managers

-

Activate information sharing

Automatic generations of various reports through the system

Send daily report email

Reduced workload and management costInspection/result data can be converted into a database that can be shared real-time between related departments to be utilized in various analysis

-

Enhanced quality level of equipment inspection

Ensured data accuracy and improved inspection efficiency

Improved equipment operation availabilityPrevention of equipment risks through standard value setting, early warning rule setting, alarm setting, etc.

-

Work standardization

Standardization of inspection process

Standardization of inspection items, cycles, units, and methodsEnhanced reliability through inspection process standardization

Establishment of an advanced system in terms of cost-effectivenessStandardization of daily inspection at all business sites

Product inquiry

02-555-7401

smart@wezon.com

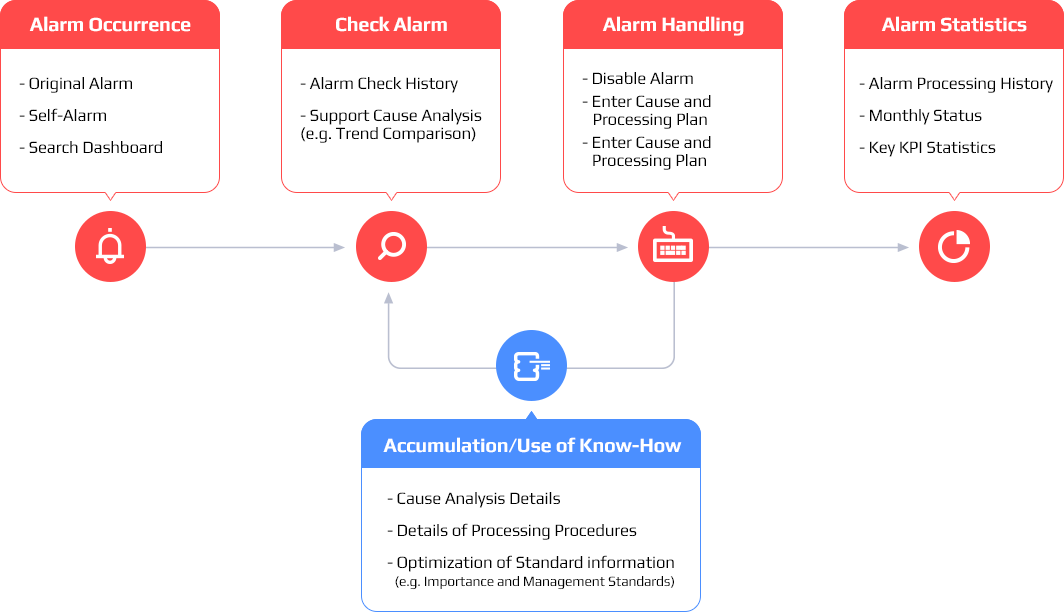

Alarm Monitoring System

Alarm Monitoring System(AMS)

Alarm occurrence trend by importance

Distribution by alarm type

Alarm Monitoring System(AMS) collects, manages, analyzes alarm data generated from DCS, RTDB, and process monitoring systems and provides the result to users.

The goal of alarm management is to reduce the number of alarms and provide operators with a consistent and stable action event notification interface for safe

and efficient operation.

Main functions include alarm frequency monitoring, multivariate analysis, alarm time management, trend in alarm occurrences by importance, alarm generation and notification, etc.

Importance

By securing an integrated alarm management system by establishing an alarm monitoring system,

we manage alarms in compliance with the international guidelines and standards of EEMUA 191 and ISA 18.2,

providing an environment where we can focus on alarms related to operational safety/loss, and thereby contributing optimal

process operation and safe operation.

System

configuration

diagram

Key functions

| Alarm frequency |

|---|

Alarm flood |

Alarm occurrence rate |

Top 20 Bad Actors |

Repeated alarm |

| Alarm status |

Importance distribution(by setting) |

Importance distribution(by occurrence) |

Hold alarm |

Alarm standard change history |

| Alarm time management/Other indicators |

|---|

Long-term alarm(24 Hours) |

Alarm responsitivity analysis |

Operator event frequency |

Alarm vs Event |

| Alarm statistics |

Stand KPI indicator |

ANSI/ISA18.2 |

EEMUA191 |

Hold alarm |

| Alarm collection(DCS) |

|---|

Yokogawa |

Azbil |

Emerson |

Metso |

Honeywell |

Serial / OPC A&E |

| Basic information |

Tag |

Plant |

Boardman Group |

Expectations

-

Supports systematic management and enhanced operational safety and productivity

Supports systematic management of alarm information and enhanced operational safety and productivity

-

Establishment of internal standard

Establishment of internal standard for alarm management

-

Management upgrade

Upgrade in alarm management method

-

Streamlined data management

Streamlined alarm data management

-

Analysis and support

Support for alarm analysis work

Product inquiry

02-555-7401

smart@wezon.com

Multivariate Analysis Mate

Multivariate statistics procedure analysis system MVAmate

Data pre-processing and statistics

Procedure status analysis and prediction through modeling

Cause analysis for abnormalities

Online monitoring and alarm system through

real-time data analysis

Multivariate statistical process analysis systems are algorithms that can be used to extract important information from large multivariate data sets, such as plant data.

MVAmate uses statistical methods to provide users with information on current and past process status using information collected through sensors in the process.

Main functions include process data statistics through data preprocessing, process status monitoring, alarms for abnormalities, and cause analysis.

Importance

-

01

Enhanced productivity

Increased production continuity through early detection and actions on equipment abnormalities

Production management based on objective data

Increased productivity by producing uniform quality products

-

02

Real-time monitoring

Improved predictive/preventive maintenance capabilities through real-time monitoring

Improved problem analysis and response capabilities

Immediate identification of abnormal data

-

03

Objective quality analysis

Identify causes of changes in process quality, process capabilities and status

Comparison of data characteristics by factor

Comparison of data trends through various graphs

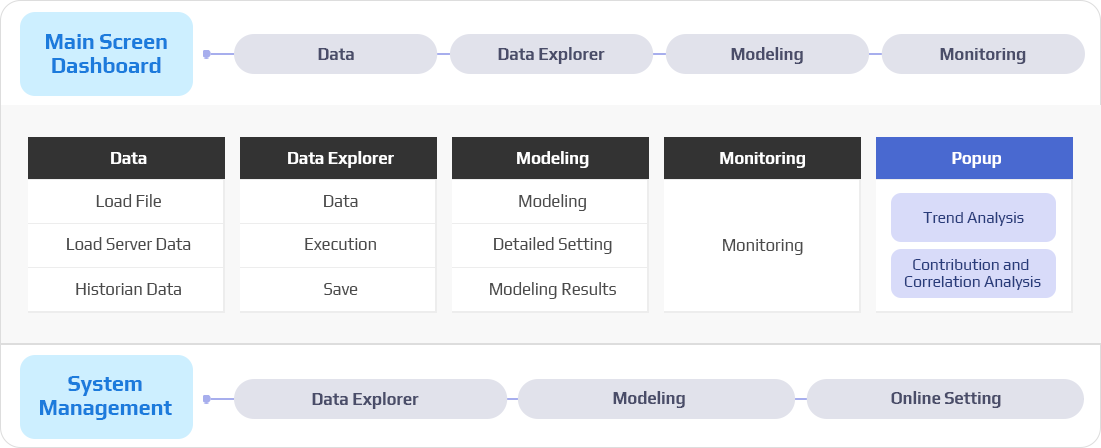

System

configuration

diagram

Key functions

| Data |

|---|

Load excel data |

Edit excel data |

Export excel data |

Connect process data |

Process data group(by tag) |

| Data Explorer |

Data standardization |

Missing data analysis |

Fault Sensor analysis |

Analyze outliers |

Analyze trends |

Analyze by group |

| Modeling |

|---|

Modeling |

Process Condition Analysis(PCA) |

Quality Prediction Analysis(PLS) |

Data analysis |

Tag correlation analysis |

Process deviation score |

Tag contribution analysis |

Trend analysis |

Analysis by group |

| Monitoring |

|---|

Model monitoring |

Real time process status |

Real time quality prediction |

Data analysis |

Tag trend analysis |

Real time alarm |

Abnormal status alarm |

Real time data connection |

| System management |

Preprocessing algorithm setting |

Modeling control level setting |

User management |

Expectations

-

Improved data quality

Diagnose abnormal sensors through diagnosis on lost data, broken sensor data, etc.

Improved data quality through correction of abnormal data such as lost data, outliers, data noise, etc.

-

Detect abnormality through dimensionality reduction

Reduced data dimensionality through data analysis and modeling

Detect abnormal data in reduced dimensions and analyze the cause of abnormalities

-

Data correlation analysis

Correlation analysis between process variables through Principal Component Analysis(PCA)

Correlation analysis between process variables and quality variables using Partial Least Squares(PLS)

-

Real-time data monitoring

Apply real-time data to models built on existing data

Detect process deviations through real-time monitoring within the model

Product inquiry

02-555-7401

smart@wezon.com